NEWS

What aspects should be paid attention to in flange die forging process

- Categories:News

- Author:

- Origin:

- Time of issue:2022-03-15 13:17

- Views:

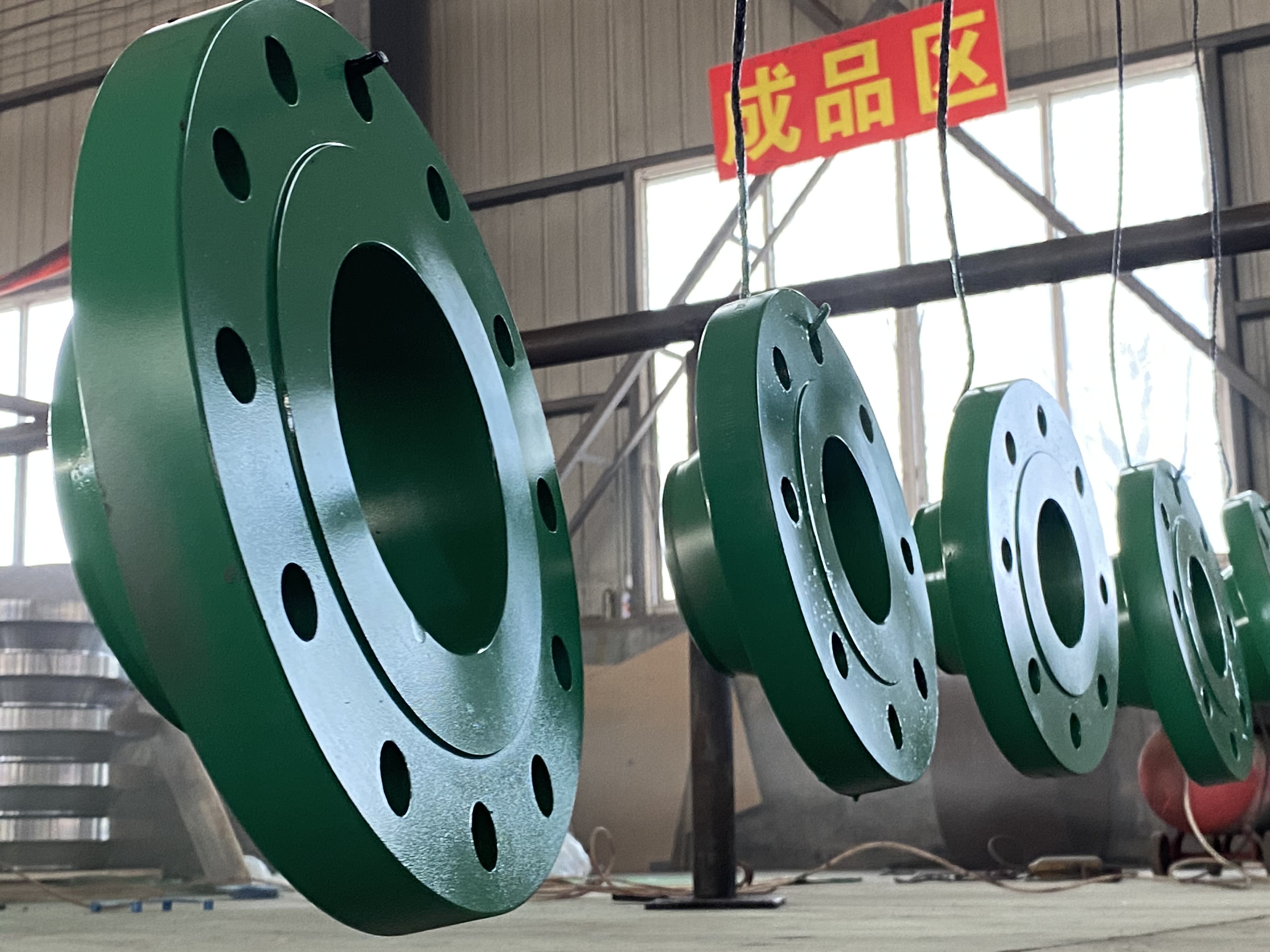

(Summary description)According to the classification of flanges and the metal flow characteristics of various flanges, the selection of die forging process is closely related to the blank specification.

What aspects should be paid attention to in flange die forging process

(Summary description)According to the classification of flanges and the metal flow characteristics of various flanges, the selection of die forging process is closely related to the blank specification.

- Categories:News

- Author:

- Origin:

- Time of issue:2022-03-15 13:17

- Views:

Flange forging process is one of the most important parts in the process of die forging, it is related to what steps to take to forge the flange required. The following points should also be considered in the selection of flange die forging process:

(1)The size and deformation of each working step of the forming process should be determined according to the allowable deformation degree and critical deformation degree of the flange material to prevent cracks and low coarse crystal structure during die forging.

(2)The forming method of increasing hydrostatic stress should be selected for low plastic materials.

(3) The direction of the gold bending fiber in the blank should be reasonable to avoid obvious bending, cutting, eddy current and other defects.

(4) According to the plastic and forging temperature range of flange materials, as well as the flange metal fiber direction and shape, production conditions, production and other factors, choose free forging billet, special equipment billet or die forging billet.

(5) Lubricants and their application methods and application sites must be indicated.

(6) It should be clearly stipulated when the die forging feeding direction, the method of removing oxide scale, the size of hammer force and underpressure and the method of taking out forgings from the die bore.

Scan the QR code to read on your phone

Tel: +86 157 2731 7311

Tel: +86 157 2731 7311

E-mail: sales@whsteelfittings.com

Factory Add:Zhenggang Industrial Park, Yanshan County, Cangzhou City Hebei Province, China.

Tel: +86 157 2731 7311

Tel: +86 157 2731 7311

E-mail: sales@whsteelfittings.com

Office Add:No.8013 FuHuaHongYan Building,HongYan South road,Chaoyang District ,Beijing ,P.R.CHINA

SOCIAL MEDIA

Copyright © 2020 WH-STEEL 冀ICP备20009811号 Powered by www.300.cn