NEWS

How to deal with leakage of high-pressure flange seal

- Categories:News

- Author:

- Origin:

- Time of issue:2022-05-16 13:39

- Views:

(Summary description)The sealing structure of the high-pressure flange lens pad is as follows: the sealing surface on both sides of the lens pad is spherical, the bevel of the tube end contacts the conical sealing surface, and the Angle between the tube end and the lens pad is about 20 degrees.

How to deal with leakage of high-pressure flange seal

(Summary description)The sealing structure of the high-pressure flange lens pad is as follows: the sealing surface on both sides of the lens pad is spherical, the bevel of the tube end contacts the conical sealing surface, and the Angle between the tube end and the lens pad is about 20 degrees.

- Categories:News

- Author:

- Origin:

- Time of issue:2022-05-16 13:39

- Views:

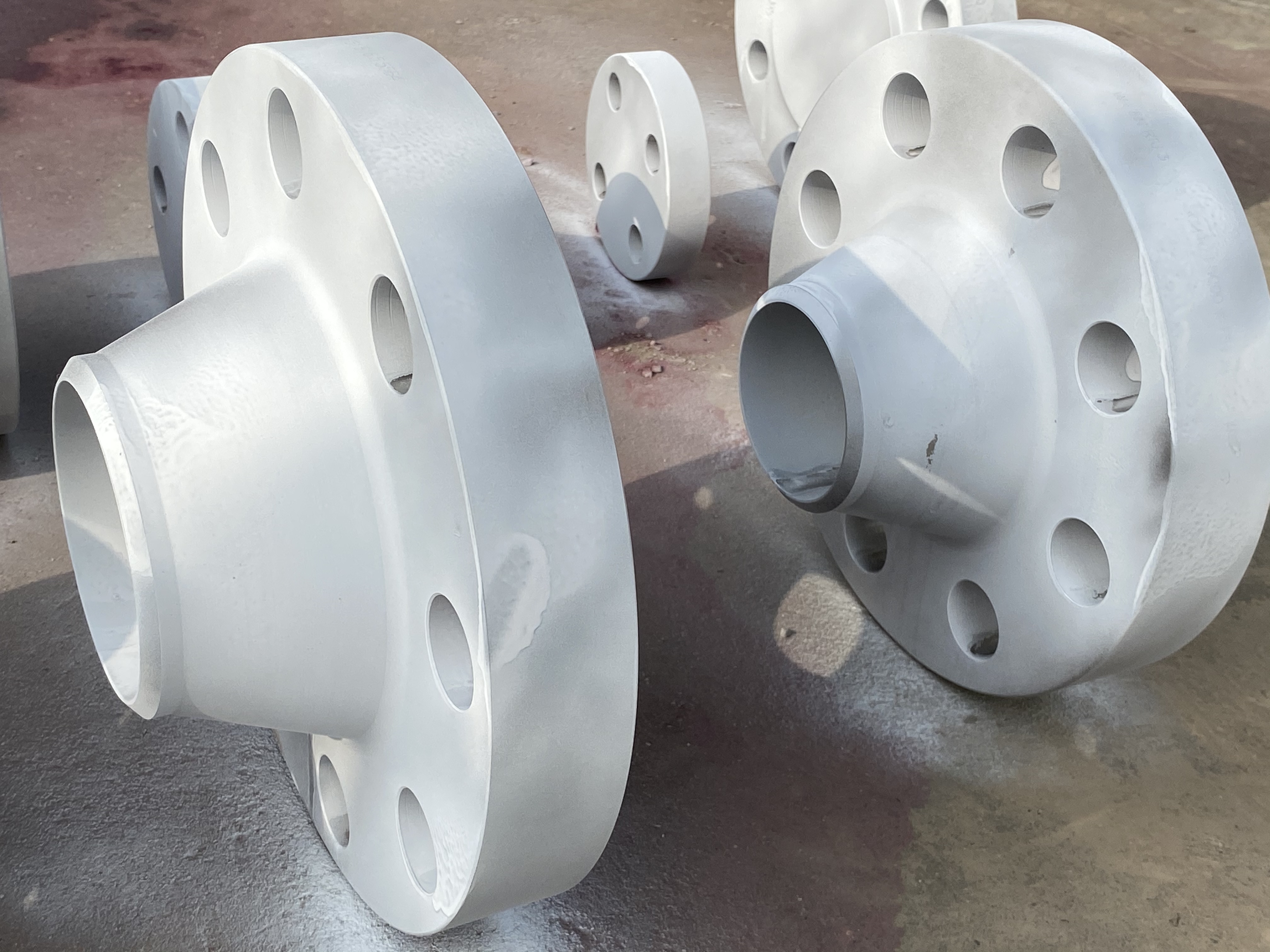

The sealing structure of the high-pressure flange lens pad is as follows: the sealing surface on both sides of the lens pad is spherical, the bevel of the tube end contacts the conical sealing surface, and the Angle between the tube end and the lens pad is about 20 degrees. The initial state is a complete circular line. Under the action of bolt pretightening force, the lens pad produces plastic deformation at the contact point, and the loop line becomes an annular belt, which ensures the reliable sealing of high pressure pipeline.

Such high-pressure flanges leak more in the process of use, so this high-pressure flange leakage is more common, what can be done to reduce the occurrence of this situation appropriately?

- Leakage elimination method

The most basic method to eliminate leakage is to increase the flange bolt preload and repair or replace the sealing element. The high-pressure lens pad is easy to disassemble and cheap, and is generally treated by removing the light knife or replacing it with a new method. For high pressure pipelines, especially those with large diameter, it is difficult to replace, disassemble, transport and manufacture, so it is not economical. It is advisable to adopt the method of on-site repair. If the sealing surface of the pipe end is partially damaged, it can be repaired by spot welding the damaged area and then grinding the sealing surface and coloring or magnetic particle inspection.

- Leakage reduction measures

Most of the lens gasket sealing leakage is interface leakage, which occurs at the interface between the lens gasket sealing sphere and the tube end conical sealing surface, mainly caused by pipeline vibration, poor assembly, medium corrosion, process fluctuation and other reasons. According to the specific causes of leakage, combined with the actual site, take effective preventive measures.

Scan the QR code to read on your phone

Tel: +86 157 2731 7311

Tel: +86 157 2731 7311

E-mail: sales@whsteelfittings.com

Factory Add:Zhenggang Industrial Park, Yanshan County, Cangzhou City Hebei Province, China.

Tel: +86 157 2731 7311

Tel: +86 157 2731 7311

E-mail: sales@whsteelfittings.com

Office Add:No.8013 FuHuaHongYan Building,HongYan South road,Chaoyang District ,Beijing ,P.R.CHINA

SOCIAL MEDIA

Copyright © 2020 WH-STEEL 冀ICP备20009811号 Powered by www.300.cn