NEWS

Get it Right! The Ultimate Elbow Installation Tutorial

- Categories:News

- Author:

- Origin:

- Time of issue:2023-09-25 10:17

- Views:

(Summary description)Installing elbows is an important step in the pipeline system. Below, we will introduce the process of installing elbows.

Get it Right! The Ultimate Elbow Installation Tutorial

(Summary description)Installing elbows is an important step in the pipeline system. Below, we will introduce the process of installing elbows.

- Categories:News

- Author:

- Origin:

- Time of issue:2023-09-25 10:17

- Views:

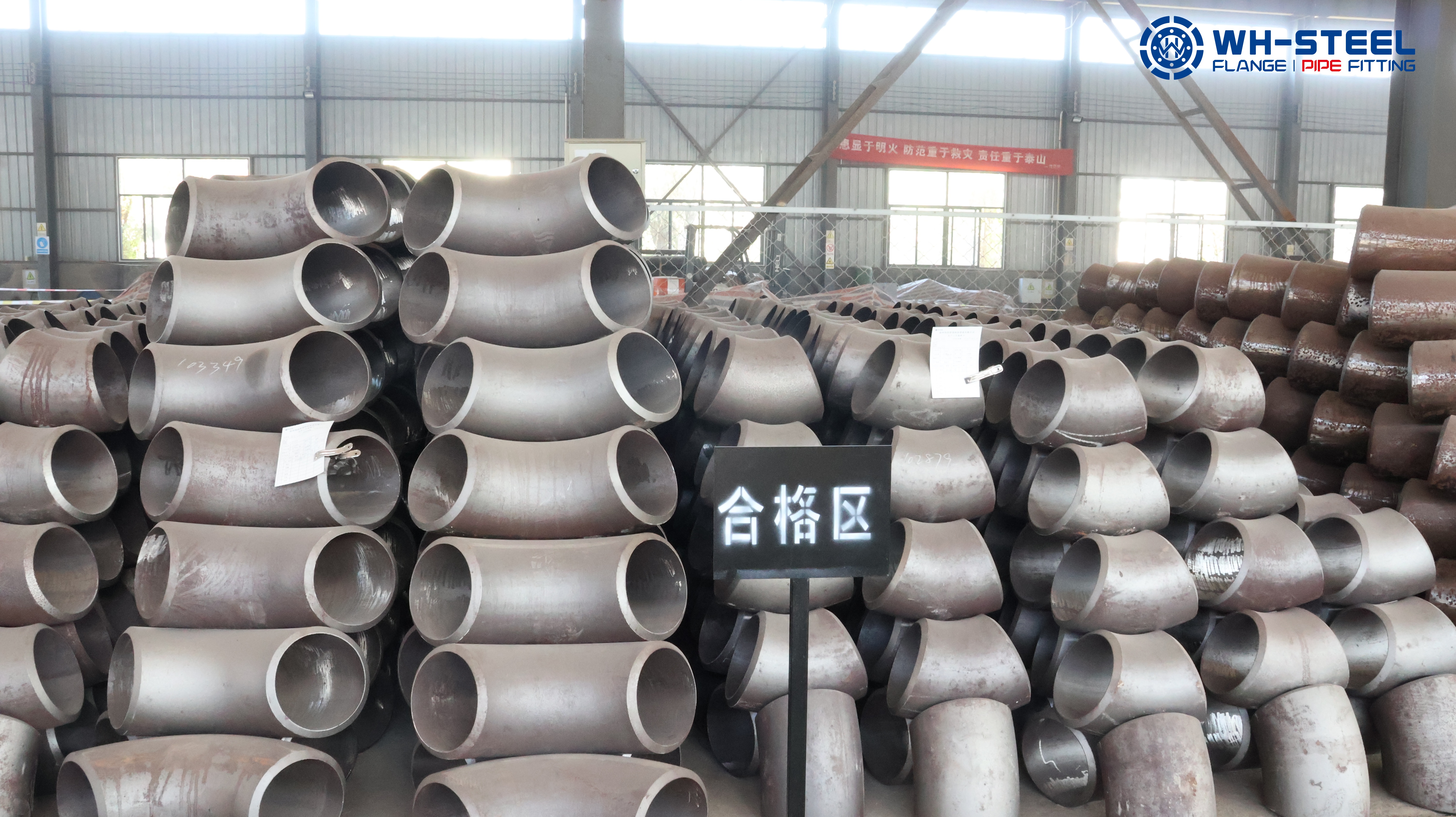

Introduction to Elbows

Elbows are commonly used to connect components in pipeline systems, used to change the direction and angle of fluid flow. The manufacturing process of elbows mainly includes material preparation, bending processing, surface treatment, and other steps. During the production process, it is necessary to select the appropriate production equipment and process based on different materials and specifications. The quality and performance of elbows directly affect the safe operation of the pipeline system.

The Process of Installing Elbows

Installing elbows is an important step in the pipeline system. Below, we will introduce the process of installing elbows.

Select the Appropriate Type of Elbow

When selecting the appropriate type of elbow, factors such as the material of the pipeline, diameter, angle, and characteristics of the fluid need to be considered. Choose either welded elbows or other types of elbows based on specific requirements and ensure their quality meets the requirements.

Prepare the Necessary Tools and Materials

Before installing elbows, it is essential to prepare the necessary tools and materials. Commonly used tools include wrenches, cutting tools, welding equipment, etc., while materials include the elbows themselves.

Measure and Mark the Pipe's Position

Before installing elbows, it is necessary to accurately measure and mark the position of the pipe. Use measuring tools to determine the length and angle of the pipe and make appropriate markings in the right places for subsequent cutting and installation work.

Cut and Process the Pipe

Based on the marked positions, use cutting tools to cut the pipe and perform the necessary processing. Ensure a smooth and even cut and take care to avoid excessive metal chips or cutting residues.

Install Elbow to Connect Pipes

Connect the prepared elbow to the cut pipe. Depending on the type of elbow, use the appropriate connection method, such as welding or threaded connections. During the connection process, ensure a tight and leak-free connection.

Inspect and Test the Installation Quality

After completing the installation, conduct an inspection and testing to verify the quality of the installation. Check if the connections are secure and perform pressure testing using the appropriate methods to ensure the reliability and safety of the pipeline system.

Scan the QR code to read on your phone

Tel: +86 157 2731 7311

Tel: +86 157 2731 7311

E-mail: sales@whsteelfittings.com

Factory Add:Zhenggang Industrial Park, Yanshan County, Cangzhou City Hebei Province, China.

Tel: +86 157 2731 7311

Tel: +86 157 2731 7311

E-mail: sales@whsteelfittings.com

Office Add:No.8013 FuHuaHongYan Building,HongYan South road,Chaoyang District ,Beijing ,P.R.CHINA

SOCIAL MEDIA

Copyright © 2020 WH-STEEL 冀ICP备20009811号 Powered by www.300.cn