NEWS

Flange Defense: Stop Corrosion and Leaks Now!

- Categories:News

- Author:

- Origin:

- Time of issue:2023-08-16 09:00

- Views:

(Summary description)If flanges are not protected, when exposed to corrosive environments or contaminated industrial atmospheres, the corrosion rate can increase rapidly. Therefore, addressing the protection of flanges against corrosion and leaks is an urgent issue that needs to be addressed.

Flange Defense: Stop Corrosion and Leaks Now!

(Summary description)If flanges are not protected, when exposed to corrosive environments or contaminated industrial atmospheres, the corrosion rate can increase rapidly. Therefore, addressing the protection of flanges against corrosion and leaks is an urgent issue that needs to be addressed.

- Categories:News

- Author:

- Origin:

- Time of issue:2023-08-16 09:00

- Views:

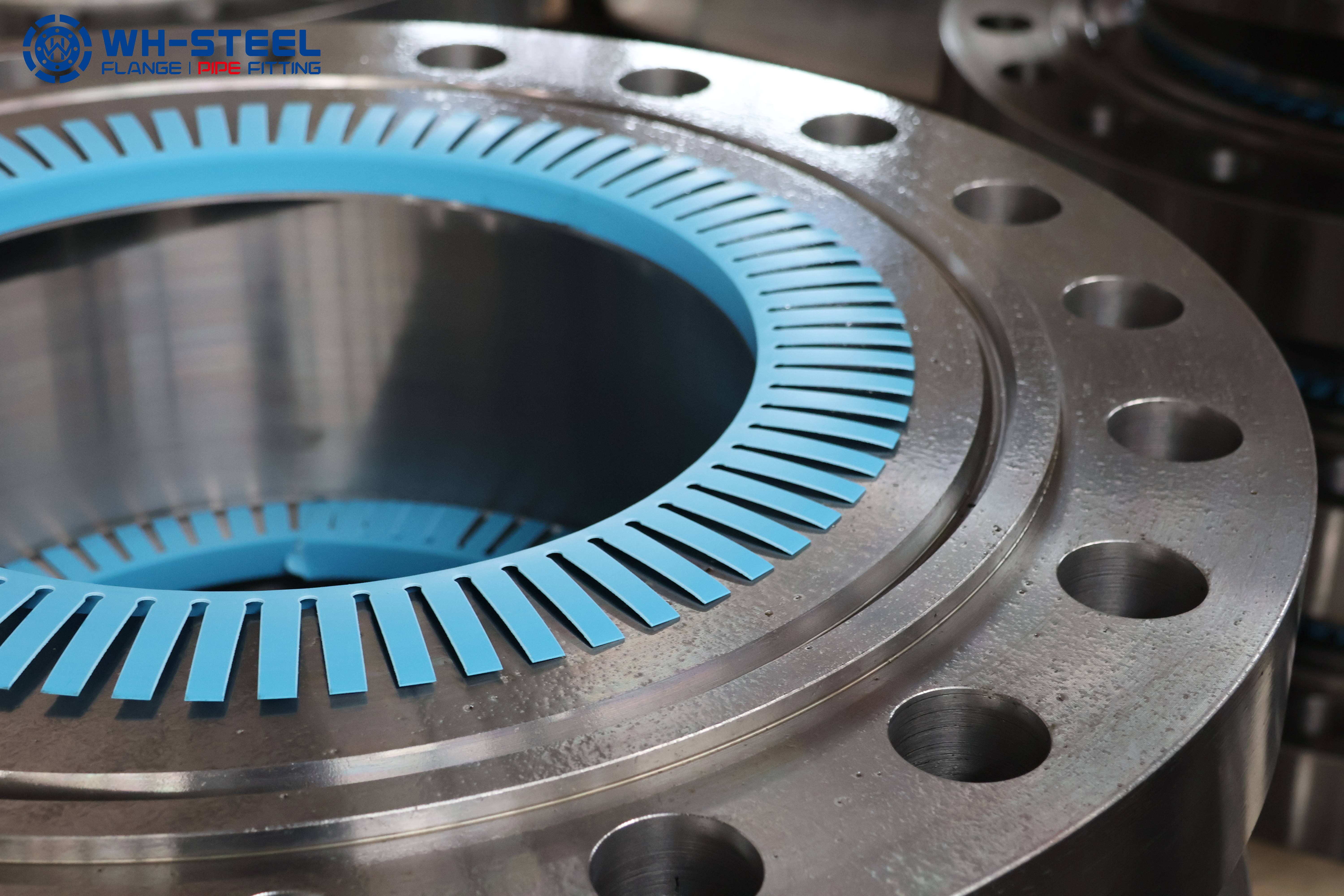

The integrity of flange connections is crucial for fluid pipeline systems. Whether it's for liquid transmission pipelines or gas lines, flange connection leaks can lead to serious environmental and economic impacts, and even pose significant safety hazards. If flanges are not protected, when exposed to corrosive environments or contaminated industrial atmospheres, the corrosion rate can increase rapidly. Therefore, addressing the protection of flanges against corrosion and leaks is an urgent issue that needs to be addressed.

Existing Solutions

An ideal solution should balance excellent corrosion protection performance with a simple construction process. It should also be adaptable to various sizes and shapes of flanges, and allow for easy bolt operation during maintenance. Currently, common solutions in the market include:

Anti-Corrosion Paint

Maintenance paint is a hard film that can be directly bonded to the substrate. It typically consists of epoxy or polyurethane coatings. Due to the many edges and corners of flanges, conventional paint systems struggle to effectively cover the edges due to the thinning effect. Although thicker coatings can solve edge protection issues, they can simultaneously seal fasteners, making subsequent disassembly during maintenance difficult. Additionally, the coating can be damaged during bolt operation, necessitating re-coating after maintenance.

Thermoplastic Solutions

Thermoplastic solutions involve applying a high-temperature heated wax-like meltable polymer onto the substrate surface using specialized equipment. The advantage of this protection method is that it can be remelted and reused, which saves costs. However, this approach requires hot work operations, specialized equipment, and construction services. While reusability is possible, reopening and sealing after maintenance can be challenging.

Tape or Semi-Solid Anticorrosive Tape Solutions

Rolled tape (such as grease tape, wax, or elastic polymer wrapping tape) is wrapped around the substrate surface for protection. This method offers reliable corrosion protection due to the good waterproof properties of semi-solid polymers. However, when the flange shape is complex, this material is not only time-consuming but also difficult to install. When disassembling bolts, the material is relatively soft and easy to cut, but it is challenging to reseal and restore the original protection after disassembly, often requiring reapplication.

Peelable Sealing Membrane System

In recent years, a popular solution has been developed to address flange corrosion. Utilizing the chemical properties of polymers, a new type of peelable sealing membrane system with both toughness and elasticity has been created. It can be forcefully peeled off without tearing, exhibiting rubber-like elasticity. Importantly, it is entirely free of isocyanates and toxic metal catalysts. However, it is prone to detachment.

Vapor Corrosion Inhibitor (VCI) Bags

Companies in the United States and Japan have developed VCI bags that can fully envelop flanges. These bags are composed of low-permeability polymers, corrosion inhibitor vapor, and desiccant. While installation is convenient, the bags are sealed at both ends with tape, rather than a durable mechanical bond. The bag's internal vapor space can accumulate a significant amount of moisture, and the corrosion inhibitor can be depleted over time. For this reason, we adopt a single-phase valve-connected sealing strip, or FEP/ECTFE + rust inhibitor (bag-shaped) approach.

Conclusion

We hope this article provides assistance in the realm of flange corrosion and leak prevention.

Scan the QR code to read on your phone

Tel: +86 157 2731 7311

Tel: +86 157 2731 7311

E-mail: sales@whsteelfittings.com

Factory Add:Zhenggang Industrial Park, Yanshan County, Cangzhou City Hebei Province, China.

Tel: +86 157 2731 7311

Tel: +86 157 2731 7311

E-mail: sales@whsteelfittings.com

Office Add:No.8013 FuHuaHongYan Building,HongYan South road,Chaoyang District ,Beijing ,P.R.CHINA

SOCIAL MEDIA

Copyright © 2020 WH-STEEL 冀ICP备20009811号 Powered by www.300.cn