NEWS

Fastening technical requirements for installation of equipment and pipe flanges

- Categories:News

- Author:

- Origin:

- Time of issue:2023-06-28 10:22

- Views:

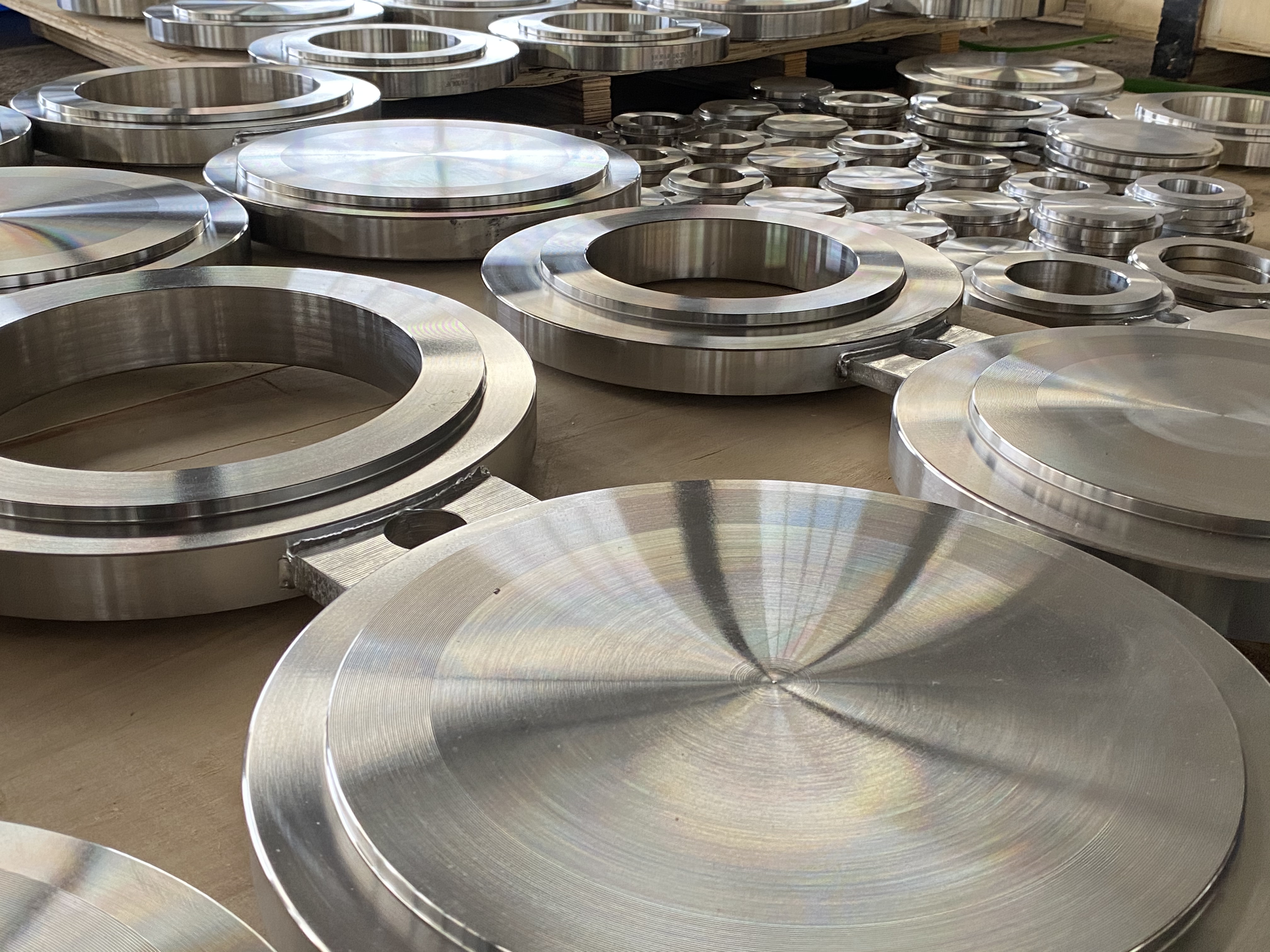

(Summary description)Suitable for general equipment and pipe flange fastening, according to bolt size and flange pressure grade selection. Fastening requirements are as follows:

Fastening technical requirements for installation of equipment and pipe flanges

(Summary description)Suitable for general equipment and pipe flange fastening, according to bolt size and flange pressure grade selection. Fastening requirements are as follows:

- Categories:News

- Author:

- Origin:

- Time of issue:2023-06-28 10:22

- Views:

Bolting method

Torque-free box wrench or hammer wrench:

Suitable for general equipment and pipe flange fastening, according to bolt size and flange pressure grade selection. Fastening requirements are as follows:

1) The maintenance unit shall formulate a fastening plan, tighten the flange symmetrically, and number the fastening sequence, as shown in Figure 1 and Figure 2.

2) Position the gasket with 4 bolts at the position of 1, 2, 3, and 4, ensuring that the center of the winding gasket is within the edge of the flange.

3) Fix the positioning bolt by hand, then insert other stud bolts and hand tighten to balance the load, and ensure that at least 2 threads are exposed at each end of the nut.

4) According to the field equipment and flange, according to the fastening circle for one calculation, reasonably set the number of fastening (at least 3 times) and the pounding load (strength) of each fastening, fastening the pounding load (strength) from small to large (such as 50%, 80%, 100% increase), the loading load is not too fast and too large, to prevent the gasket seal failure.

5) Torque-free box wrench or hammer wrench each tightening sequence: tighten the radial opposite two bolts to the bolt established hammer load (force); Tighten the other pair of bolts about 90 degrees from the previous two bolts along the circumference; Continue tightening until all remaining bolts are secured to the specified hammer load.

6) Finally, tighten all bolts in a clockwise or counterclockwise direction according to 100% hammer load (force).

Scan the QR code to read on your phone

Tel: +86 157 2731 7311

Tel: +86 157 2731 7311

E-mail: sales@whsteelfittings.com

Factory Add:Zhenggang Industrial Park, Yanshan County, Cangzhou City Hebei Province, China.

Tel: +86 157 2731 7311

Tel: +86 157 2731 7311

E-mail: sales@whsteelfittings.com

Office Add:No.8013 FuHuaHongYan Building,HongYan South road,Chaoyang District ,Beijing ,P.R.CHINA

SOCIAL MEDIA

Copyright © 2020 WH-STEEL 冀ICP备20009811号 Powered by www.300.cn