NEWS

What are the effects of mechanical cutting on the quality of heat-treated forgings?

- Categories:News

- Author:

- Origin:

- Time of issue:2022-06-13 13:14

- Views:

(Summary description)In the forgings tempering, annealing, normalizing state, the hardness is less than 45HRC, the cutting process on the quality of forgings, including surface finish, residual stress, machining allowance, surface decarbonization and the removal of poor carbon layer, are not obvious, so as not to cause the change of potential performance of the workpiece.

What are the effects of mechanical cutting on the quality of heat-treated forgings?

(Summary description)In the forgings tempering, annealing, normalizing state, the hardness is less than 45HRC, the cutting process on the quality of forgings, including surface finish, residual stress, machining allowance, surface decarbonization and the removal of poor carbon layer, are not obvious, so as not to cause the change of potential performance of the workpiece.

- Categories:News

- Author:

- Origin:

- Time of issue:2022-06-13 13:14

- Views:

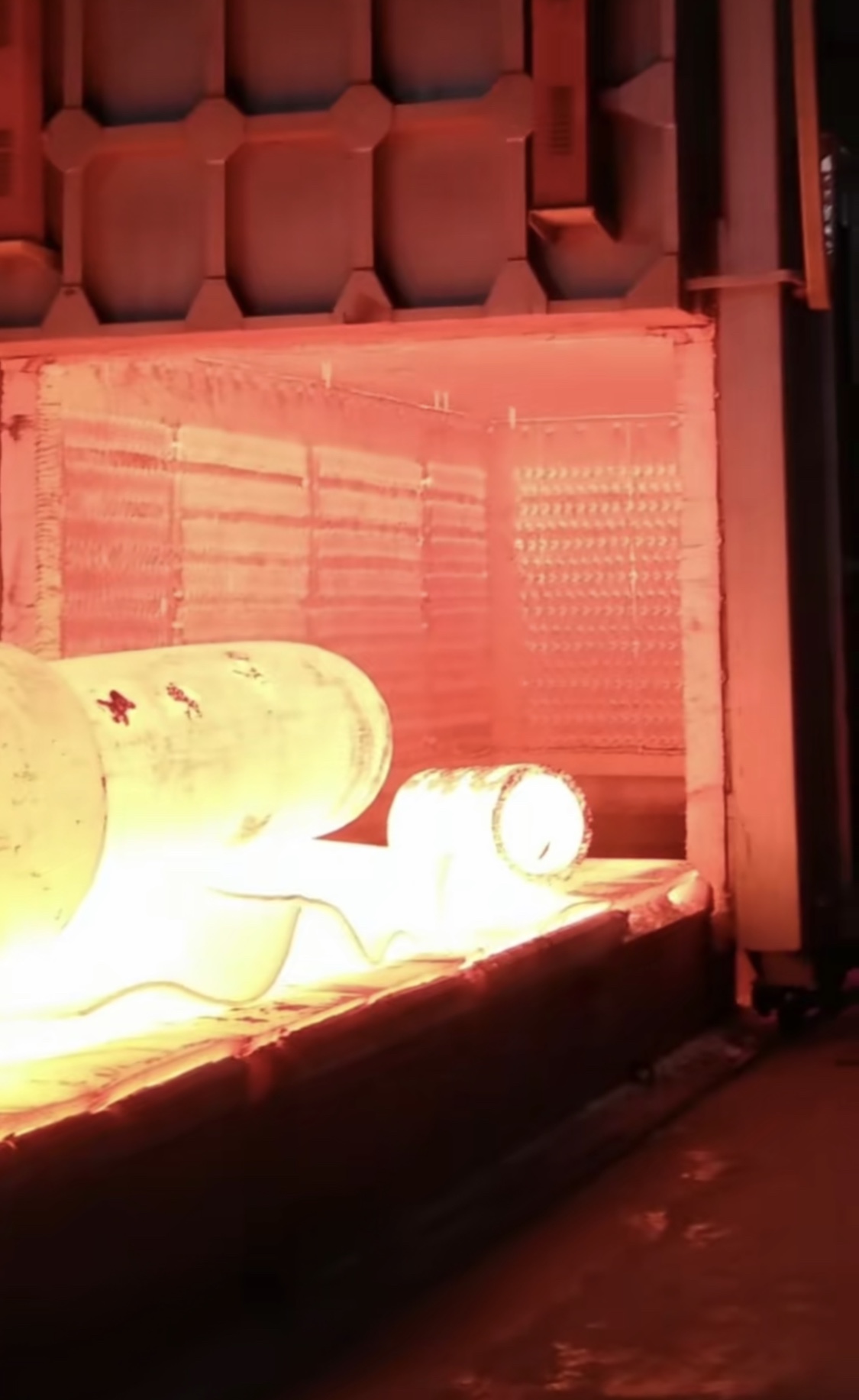

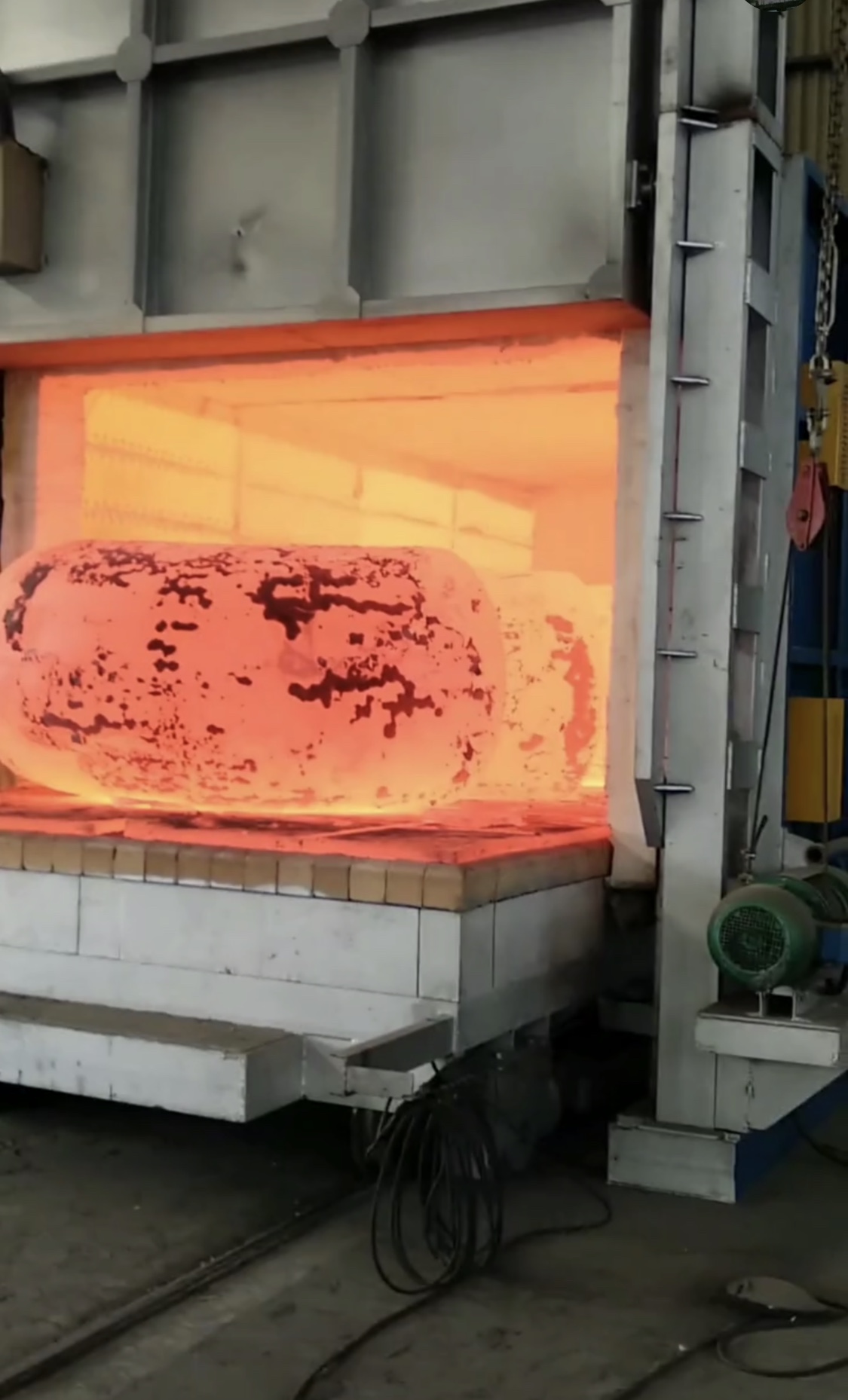

Forgings hardened steel or processing, also known as hard processing, workpiece hardness up to 50 ~ 65HRC, materials mainly include ordinary hardened steel, hardened die steel, bearing steel, roll steel and high-speed steel, etc., the impact of cutting is more obvious, In the process of cutting, the generation and conduction of cutting heat, high speed friction and wear will destroy the machined surface to a certain extent. The integrity of the machined surface in hard cutting mainly includes surface microstructure morphology and hardness, surface roughness, dimensional accuracy, residual stress distribution and white layer generation.

The hardness of machined surface increases with the cutting speed of forgings, and decreases with the increase of feed and cutting amount. And the higher the hardness of the processed surface, the greater the depth of the hardening layer. The results show that the residual compressive stress is found on the surface of the forging after hard cutting, while the maximum compressive stress is mainly concentrated on the surface of the workpiece after grinding.

The larger the tool obtuse Angle radius is, the larger the residual compressive stress is. The higher the workpiece hardness is, the higher the residual compressive stress is. Forgings hardness has a great influence on the design surface integrity, the greater the forgings hardness value, the more conducive to the formation of residual compressive stress.

Another important factor affecting the quality of machined surface in hard cutting is the formation of white layer. White layer is a kind of microstructure formed with hard cutting process, it has unique wear characteristics: on the one hand, high hardness, good corrosion resistance; On the other hand, it shows high brittleness, which is easy to cause early spalling failure, and even forming cracking after a stage of workpiece processing.

At present, the white layer is regarded as martensitic structure, but the fine structure of the white layer is controversial. One view is that the white layer is the result of phase transformation and is composed of fine grained martensite formed by rapid heating and sudden cooling of the material during cutting. Another point of view is that the formation of the white layer is only a deformation mechanism, and it is only an unconventional martensite formed by the plastic deformation of the forging.

Scan the QR code to read on your phone

Tel: +86 157 2731 7311

Tel: +86 157 2731 7311

E-mail: sales@whsteelfittings.com

Factory Add:Zhenggang Industrial Park, Yanshan County, Cangzhou City Hebei Province, China.

Tel: +86 157 2731 7311

Tel: +86 157 2731 7311

E-mail: sales@whsteelfittings.com

Office Add:No.8013 FuHuaHongYan Building,HongYan South road,Chaoyang District ,Beijing ,P.R.CHINA

SOCIAL MEDIA

Copyright © 2020 WH-STEEL 冀ICP备20009811号 Powered by www.300.cn