NEWS

Procedure for correct installation of 1D Bend products

- Categories:1D Bend

- Author:

- Origin:

- Time of issue:2022-10-19 11:23

- Views:

(Summary description)1.1D Bend products First connect the head accurately. 2. Assemble the sealing ring, the inner structure of the sealing sleeve and the cone hole of the sleeve. 3. To assemble the ferrule joint, apply lubricating grease on the inner structure of the ferrule joint and the contact position of the ferrule spherical surface, which is conducive to assembly.

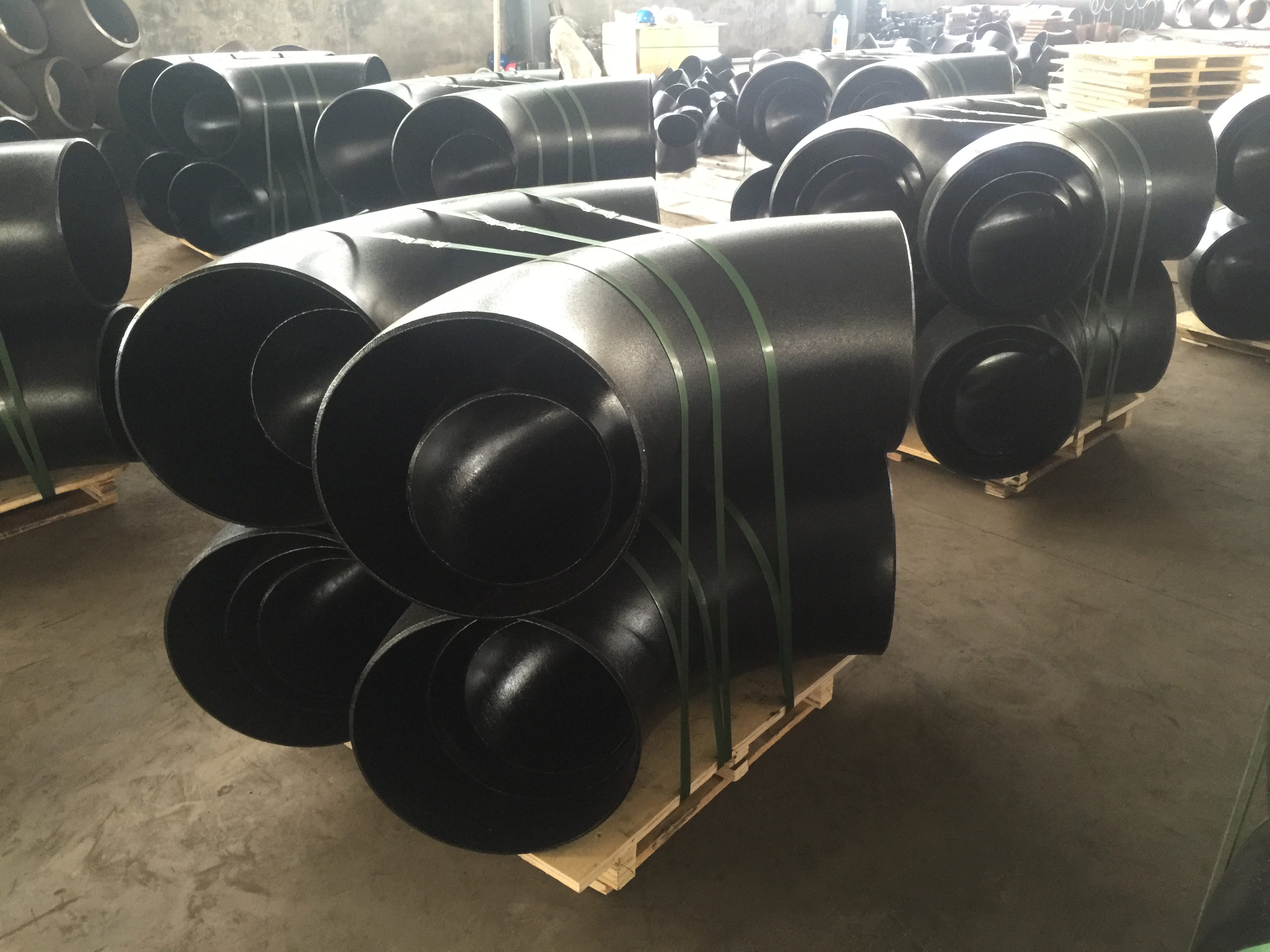

Procedure for correct installation of 1D Bend products

(Summary description)1.1D Bend products First connect the head accurately. 2. Assemble the sealing ring, the inner structure of the sealing sleeve and the cone hole of the sleeve. 3. To assemble the ferrule joint, apply lubricating grease on the inner structure of the ferrule joint and the contact position of the ferrule spherical surface, which is conducive to assembly.

- Categories:1D Bend

- Author:

- Origin:

- Time of issue:2022-10-19 11:23

- Views:

1.1D Bend products First connect the head accurately. 2. Assemble the sealing ring, the inner structure of the sealing sleeve and the cone hole of the sleeve. 3. To assemble the ferrule joint, apply lubricating grease on the inner structure of the ferrule joint and the contact position of the ferrule spherical surface, which is conducive to assembly.

4.1D Bend products Mounting bolts and curved nuts must be greased on the curved surfaces and threads to facilitate assembly. 5. The tightening nut must be gradually and symmetrically tightened in a diagonal sequence to ensure that the ferrule joint has a symmetrical part. 6. According to the standard torque nut in the product manual, a torque wrench should be selected. 7.1D After the assembly of Bend products, the reinforcement between the ports of the two joints and the sealing ring should be in close contact with gaps.

Cold-formed 1D Bend products have a very nice finish, and their size and quality count in the header, but they must be formed to meet all regulations. The production and operation of stamping elbow stamping processing is convenient, and it is convenient to complete mechanization and automation. This is because stamping is performed by means of a die, and carbon steel can be divided into low carbon steel, medium carbon steel and high carbon steel according to carbon content. 1D Bend products have different strengths and strengths in use and production, ensuring that they can play an important role and cost in use.

Scan the QR code to read on your phone

Tel: +86 157 2731 7311

Tel: +86 157 2731 7311

E-mail: sales@whsteelfittings.com

Factory Add:Zhenggang Industrial Park, Yanshan County, Cangzhou City Hebei Province, China.

Tel: +86 157 2731 7311

Tel: +86 157 2731 7311

E-mail: sales@whsteelfittings.com

Office Add:No.8013 FuHuaHongYan Building,HongYan South road,Chaoyang District ,Beijing ,P.R.CHINA

SOCIAL MEDIA

Copyright © 2020 WH-STEEL 冀ICP备20009811号 Powered by www.300.cn