NEWS

Features of seamless push elbow fittings

- Categories:News

- Author:

- Origin:

- Time of issue:2021-11-09 10:58

- Views:

(Summary description)The arrival quality of seamless push elbow pipe fittings has the following important problems: First, the wall thickness of the elbow is not uniform The non-uniform thickness of elbow pipe wall occurs mainly at the part with the largest deformation of pipe fittings.If the thickness of the pipe wall on the back of the elbow is thinner than that on other parts, the thickness of the pipe wall is not equal to that of the pipe mouth and pipe fitting body. Second, elbow hardness overspend The occurrence of seamless hardness overspend problem, if because of the forming of the heat treatment process problem, the treatment method is to use accurate heat treatment process to suspend a heat treatment. Third, elbow material defects Push elbow is the most harmful to assembly safety.Introspection is more difficult.The origin of defects is more complicated, it has its own material defects and processing technology problems and heat treatment process is not accurate defects. Fourth, bend inside the arc wrinkle When the arc interface of seamless elbow is a heating push time, the external load of these changes will constitute the welding joint in a complicated stress state, which will severely weaken the strength of the welding joint, and then reduce the welding joint, more seriously is to shorten the service life of seamless elbow. Hot push bend deformation characteristic is according to the volume before and after plastic deformation rule of metal materials determine the pipe diameter, chooses the pipe diameter less than bend diameter, through the core module and control the deformation of the process, make the inner arc metal activity is compressed, the compensation to the other parts of the thinned by expanding, then get the wall thickness of the elbow. Hot push elbow forming process has the characteristics of beautiful appearance, uniform wall thickness and continuous operation, suitable for mass production, so it has become the main forming method of carbon steel, alloy steel elbow, and also used in some standard stainless steel elbow forming.The heating method of forming process has medium frequency or high frequency induction heating (heating ring can be multi-ring or single ring), flame heating and reflector heating, which heating method to choose according to the requirements of forming products and energy conditions.

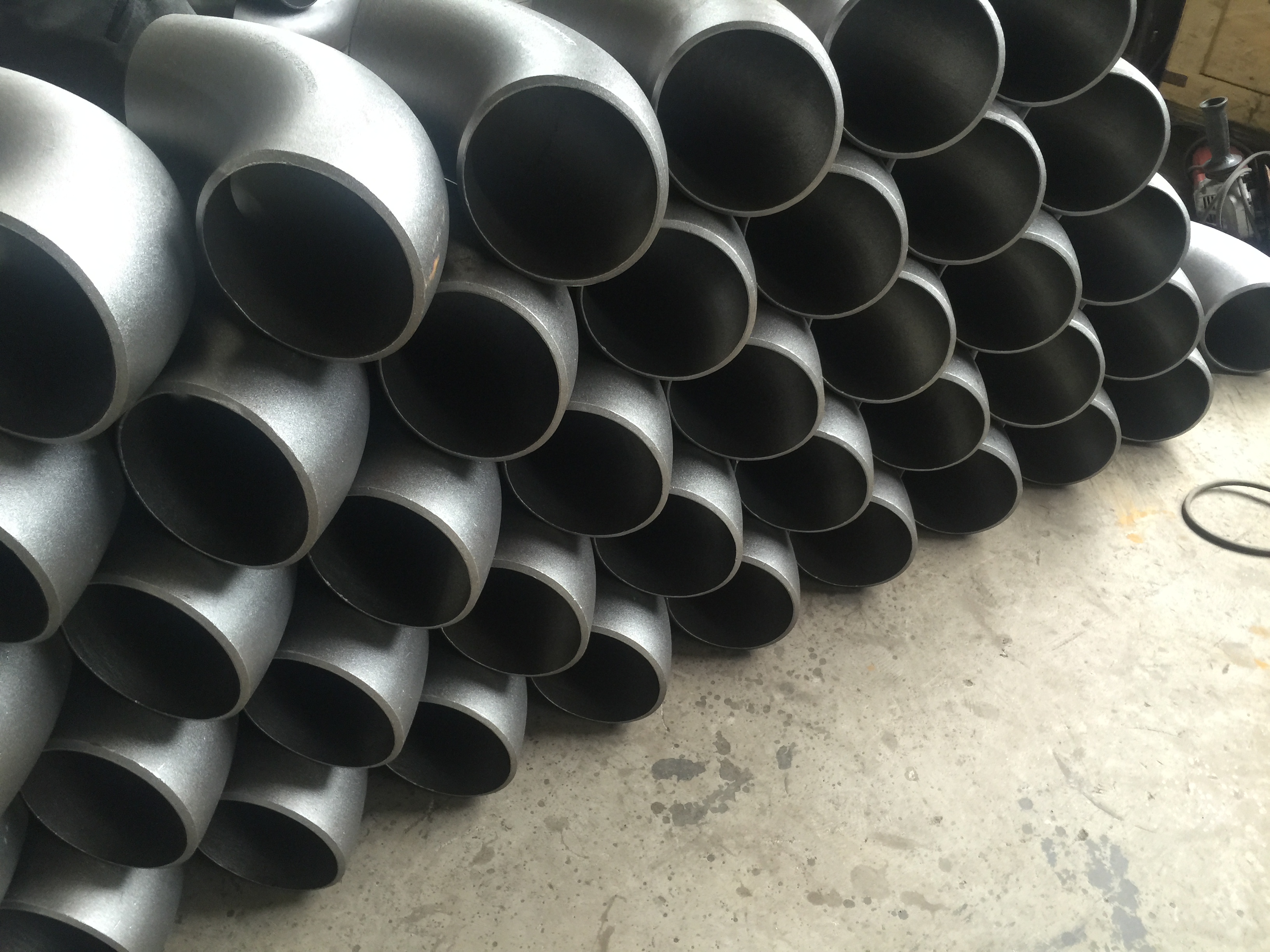

Features of seamless push elbow fittings

(Summary description)The arrival quality of seamless push elbow pipe fittings has the following important problems:

First, the wall thickness of the elbow is not uniform

The non-uniform thickness of elbow pipe wall occurs mainly at the part with the largest deformation of pipe fittings.If the thickness of the pipe wall on the back of the elbow is thinner than that on other parts, the thickness of the pipe wall is not equal to that of the pipe mouth and pipe fitting body.

Second, elbow hardness overspend

The occurrence of seamless hardness overspend problem, if because of the forming of the heat treatment process problem, the treatment method is to use accurate heat treatment process to suspend a heat treatment.

Third, elbow material defects

Push elbow is the most harmful to assembly safety.Introspection is more difficult.The origin of defects is more complicated, it has its own material defects and processing technology problems and heat treatment process is not accurate defects.

Fourth, bend inside the arc wrinkle

When the arc interface of seamless elbow is a heating push time, the external load of these changes will constitute the welding joint in a complicated stress state, which will severely weaken the strength of the welding joint, and then reduce the welding joint, more seriously is to shorten the service life of seamless elbow.

Hot push bend deformation characteristic is according to the volume before and after plastic deformation rule of metal materials determine the pipe diameter, chooses the pipe diameter less than bend diameter, through the core module and control the deformation of the process, make the inner arc metal activity is compressed, the compensation to the other parts of the thinned by expanding, then get the wall thickness of the elbow.

Hot push elbow forming process has the characteristics of beautiful appearance, uniform wall thickness and continuous operation, suitable for mass production, so it has become the main forming method of carbon steel, alloy steel elbow, and also used in some standard stainless steel elbow forming.The heating method of forming process has medium frequency or high frequency induction heating (heating ring can be multi-ring or single ring), flame heating and reflector heating, which heating method to choose according to the requirements of forming products and energy conditions.

- Categories:News

- Author:

- Origin:

- Time of issue:2021-11-09 10:58

- Views:

The arrival quality of seamless push elbow pipe fittings has the following important problems:

First, the wall thickness of the elbow is not uniform

The non-uniform thickness of elbow pipe wall occurs mainly at the part with the largest deformation of pipe fittings.If the thickness of the pipe wall on the back of the elbow is thinner than that on other parts, the thickness of the pipe wall is not equal to that of the pipe mouth and pipe fitting body.

Second, elbow hardness overspend

The occurrence of seamless hardness overspend problem, if because of the forming of the heat treatment process problem, the treatment method is to use accurate heat treatment process to suspend a heat treatment.

Third, elbow material defects

Push elbow is the most harmful to assembly safety.Introspection is more difficult.The origin of defects is more complicated, it has its own material defects and processing technology problems and heat treatment process is not accurate defects.

Fourth, bend inside the arc wrinkle

When the arc interface of seamless elbow is a heating push time, the external load of these changes will constitute the welding joint in a complicated stress state, which will severely weaken the strength of the welding joint, and then reduce the welding joint, more seriously is to shorten the service life of seamless elbow.

Hot push bend deformation characteristic is according to the volume before and after plastic deformation rule of metal materials determine the pipe diameter, chooses the pipe diameter less than bend diameter, through the core module and control the deformation of the process, make the inner arc metal activity is compressed, the compensation to the other parts of the thinned by expanding, then get the wall thickness of the elbow.

Hot push elbow forming process has the characteristics of beautiful appearance, uniform wall thickness and continuous operation, suitable for mass production, so it has become the main forming method of carbon steel, alloy steel elbow, and also used in some standard stainless steel elbow forming.The heating method of forming process has medium frequency or high frequency induction heating (heating ring can be multi-ring or single ring), flame heating and reflector heating, which heating method to choose according to the requirements of forming products and energy conditions.

Scan the QR code to read on your phone

Tel: +86 157 2731 7311

Tel: +86 157 2731 7311

E-mail: sales@whsteelfittings.com

Factory Add:Zhenggang Industrial Park, Yanshan County, Cangzhou City Hebei Province, China.

Tel: +86 157 2731 7311

Tel: +86 157 2731 7311

E-mail: sales@whsteelfittings.com

Office Add:No.8013 FuHuaHongYan Building,HongYan South road,Chaoyang District ,Beijing ,P.R.CHINA

SOCIAL MEDIA

Copyright © 2020 WH-STEEL 冀ICP备20009811号 Powered by www.300.cn