NEWS

Differences between hot forging and cold forging of flange pipe fittings

- Categories:News

- Author:

- Origin:

- Time of issue:2022-04-26 14:56

- Views:

(Summary description)About hot forging: in hot forging, large flanged pipe fittings with complex shapes can be cast because of the small deformation energy and resistance.

Differences between hot forging and cold forging of flange pipe fittings

(Summary description)About hot forging: in hot forging, large flanged pipe fittings with complex shapes can be cast because of the small deformation energy and resistance.

- Categories:News

- Author:

- Origin:

- Time of issue:2022-04-26 14:56

- Views:

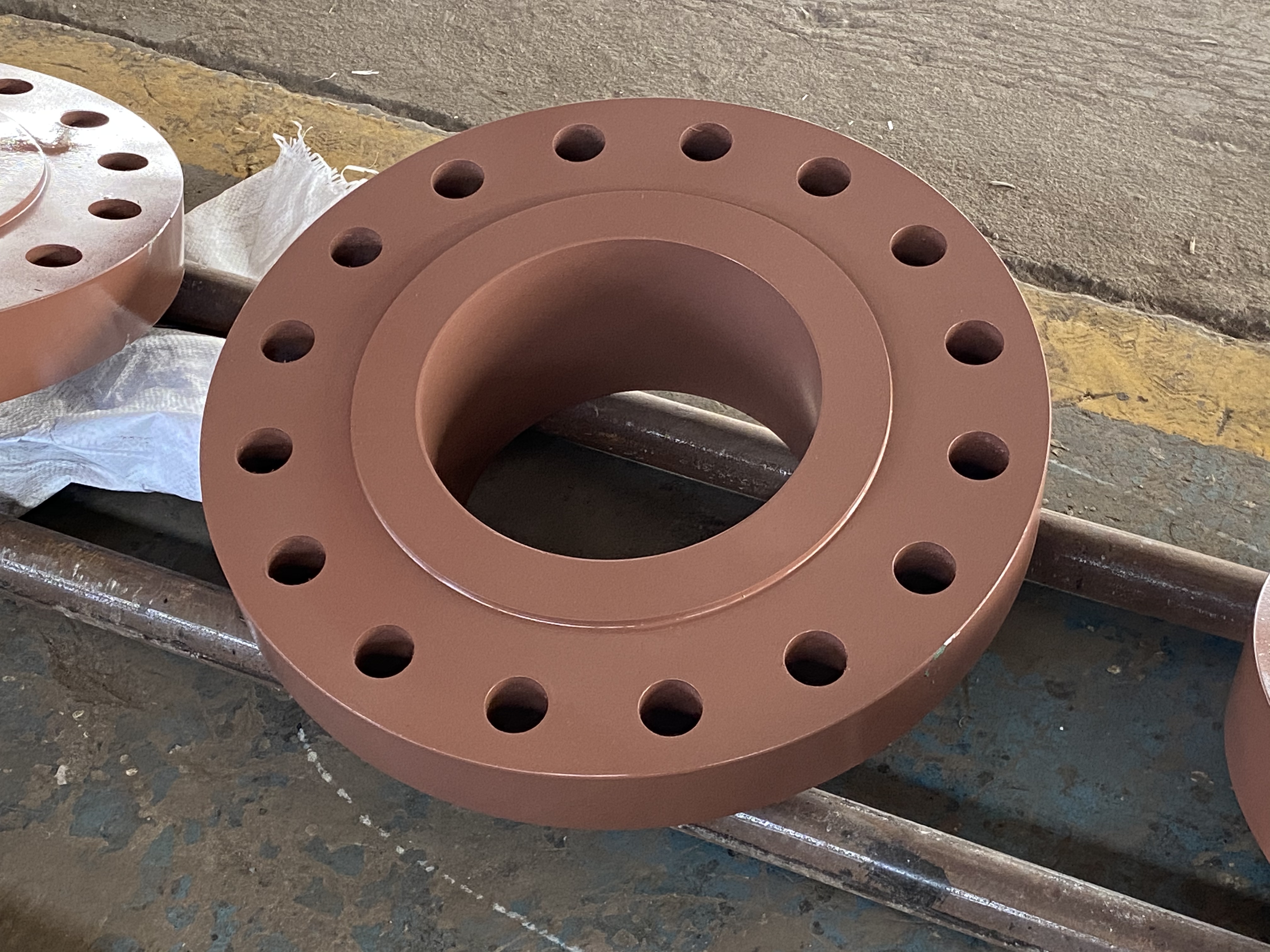

About hot forging: in hot forging, large flanged pipe fittings with complex shapes can be cast because of the small deformation energy and resistance. High scale precision flange fittings can be processed by hot forging in the temperature range of 900-1000℃. In addition, attention should be paid to improving the working environment of hot forging. Forging die life (hot forging 2-5 thousand, warm forging 10-20 thousand, cold forging 20-50 thousand) is shorter than other temperature range casting, but it has a large degree of freedom, low cost. The purpose of hot forging flange pipe fittings is mainly to reduce the deformation resistance of metal, so reduce the forging pressure required by bad deformation, so that the tonnage of forging equipment is greatly reduced; The as-cast structure of the steel ingot used for flange pipe fittings is modified. The coarse as-cast arrangement is changed into a new arrangement of fine grains by recrystallization in the process of hot forging, and the defects of as-cast structure are reduced to improve the mechanical properties of steel.

The cold forging of flanged pipe fittings is in low temperature casting, the scale of flanged pipe fittings changes little. When cast below 700℃, the oxide scale has little composition and no decarbonization on the surface. Therefore, as long as the deformation energy is within the forming energy range, cold forging is easy to obtain good scale accuracy and surface finish. As long as the temperature and smooth cooling are controlled, warm forging under 700℃ can obtain good accuracy. Cold forging, cold extrusion, cold heading and other plastic processing. Cold forging is the molding process of the material below the recrystallization temperature, and the casting is carried out below the recovery temperature. In production, the casting process without heating the blank is called cold forging. Cold forging materials are mostly aluminum and some alloys, copper and some alloys, low carbon steel, medium carbon steel and low alloy structural steel with small deformation resistance and good plasticity at room temperature. Cold forging surface quality, high precision scale, can replace some cutting. Cold forging can strengthen the metal and improve the strength of flange pipe fittings.

The development of cold forging skills is mainly to develop high value-added products, reduce production costs, together, it is also constantly to the cutting, powder metallurgy, casting, hot forging, sheet metal forming process and other categories of penetration or replacement, can also be combined with these processes to form a composite process.

Scan the QR code to read on your phone

Tel: +86 157 2731 7311

Tel: +86 157 2731 7311

E-mail: sales@whsteelfittings.com

Factory Add:Zhenggang Industrial Park, Yanshan County, Cangzhou City Hebei Province, China.

Tel: +86 157 2731 7311

Tel: +86 157 2731 7311

E-mail: sales@whsteelfittings.com

Office Add:No.8013 FuHuaHongYan Building,HongYan South road,Chaoyang District ,Beijing ,P.R.CHINA

SOCIAL MEDIA

Copyright © 2020 WH-STEEL 冀ICP备20009811号 Powered by www.300.cn